Produzione di alcool neutro: simulazione di un'unità di distillazione

Description:

"Production of neutral alcohol: simulation of a distillation unit"

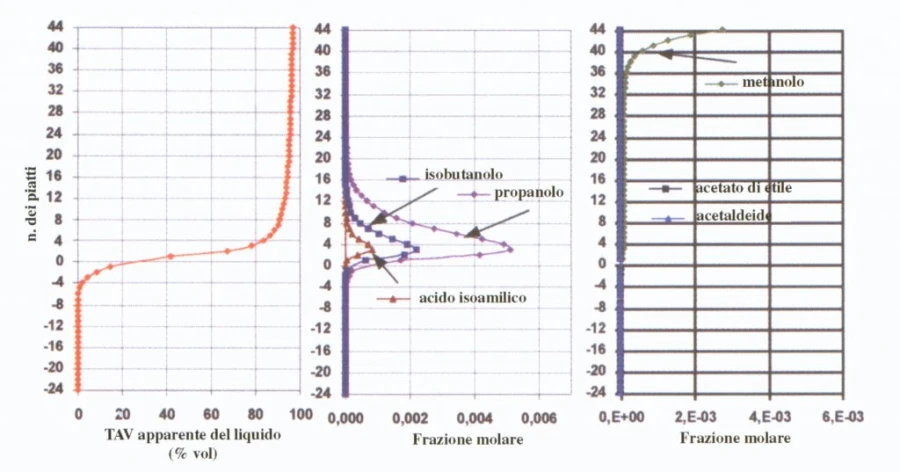

Our goal was to simulate the operation of distillation columns used in the neutral alcohol production from fermented juice with the help of the ProSim Plus programme. It has been used a model solution consisting of water, ethanol and 6 representative non-alcohols (acetaldehyde, ethyl acetate, propanol, isobutanol, isoamyl alcohol). For the thermodynamic model we have selected two models that might be suitable for the alcoholic solutions . The comparison of the predictions provided by these two models, with data published by a Japanese group, has allowed to choose the UNIFAC model. The simulations were performed for the whole unit consisting of 7 columns in series (2 for reproducing the intermediate alcohol and 5 to switch to the neutral alcohol ). Thanks to the simulation, it has been possible to demonstrate the role of each column: the unit which deals with the fermented juice has produced an intermediate alcohol product which content in isoamyl alcohol was greatly reduced; the extractive distillation column removes most of ethyl acetate and acetaldehyde and half of the higher alcohols, but it has no action on methanol; the rectifying column can eliminate the remaining higher alcohols; finally, the demethylizer column is essential to eliminate methanol. The concentration column of associated products, combined with the lightening column allows to concentrate the ethanol to respond to commercial needs, and especially to recycle towards the extractive distillation column the 55% of the ethanol introduced with the extractions taken out from the head of the extractive distillation column and the extractions of oil from the rectifying column.

-

If you wish to download the entire document, please send a request to info@grappa.com specifying the title of the text you wish to receive, the reason for this request and full applicant details.

Thank you.

POLI GRAPPA MUSEUM

Biographical Notes:

Photogallery:

Request Document

To download the entire document, please send a request by filling out the form.

The fields marked with (*) are mandatory

Download Document

Log in to access reserved documents.